In the world of commercial and residential construction, products and solutions are always changing. One type of product that is working to take a new approach in the construction industry is Insulated Concrete Forms (ICFs). Insulated Concrete Forms are a system of form work for reinforced concrete, usually made with a rigid thermal insulation that stays in place.

ICFs are forms, made from expanded plystyrene (EPS) high-density foam, left in place permanently to serve as thermal and acoustic insulation, space to run electrical wiring and plumbing, and backing for interior gypsum board and exterior facades.

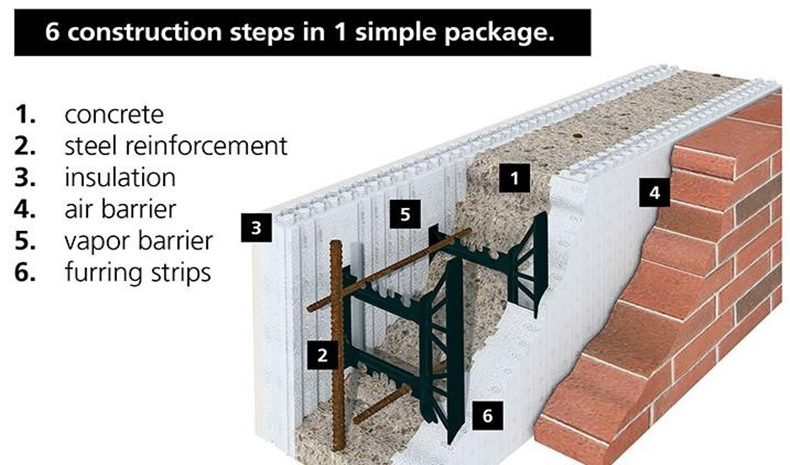

The forms are interlocking modular units that are dry-stacked and filled with concrete. ICF units lock together and create a form for the structural walls of a building. The forms are considered among many to be an effective "one-step assembly."

Here are some of the key basics of ICF construction.

ICF Construction

Reinforced steel bars (rebar) are usually placed inside the forms before concrete is poured to give the concrete flexural strength (similar to bridges and high-rises). Some advantages to ICF construction include:

1. Space to run electrical wires and plumbing

Plumbing and electrical conduit can be placed inside the forms and poured into place, though settling problems could cause the pipes to crack, creating costly repairs. For this reason, plumbing and electrical conduit as well as electrical cables are usually embedded directly into the foam before the wall coverings are applied.

2. Ease of Installation

With ICF, construction steps can be condensed into just six simple steps, as many different building components are being rolled into one product. The blocks then stack together, almost as if they were Legos pieces. During construction, ICF blocks are fitted together, laced with rebar, and filled with concrete.

3. Speed of Construction

Speed of construction comes from the fact that only one trade is needed. Even in winter conditions, you won't need to install exterior cladding; once the building is enclosed, interior work can be done. Home construction can be completed weeks ahead of wood framing, and commercial buildings can be completed months ahead of any other method.

4. Winter Construction

ICFs can be constructed in the winter at lower temperatures without the need for insulating blankets or a heating source. ICF construction is highly energy-efficient thanks toi insulating properties within the wall structure. By design, ICFs retain much of the heat generated during the concrete curing. Because of the ability to built with ICFs at any temperature, construction companies are uaully able to stay on schedule, even during weather conditions that could make it difficult.

ICF Characteristics

1. Strength

Insulated concrete forms create a structural concrete wall that is up to ten times stronger than wood-framed structures. ICFs have better structural integrity compared to framed walls for better resistance to the forces of nature.

2. Sound Absorption

ICF walls have much lower rates of acoustic transmission. The level of sound attenuation achieved is a function of the wall thickness, mass, component materials, and airtightness found within ICF.

3. Fire Protection

ICF walls can have a four-hour to six-hour fire-resistant rating. Unlike wood, concrete does not burn, and unlike steel, it does not soften or bend. ICF walls have been tested at up to 2,000 degrees Fahrenheit (typical for a common house fire), where wood walls would typically collapse within an hour.

4. Indoor Air Quality

Because they are generally constructed without a sheet plastic vapor barrier, ICF walls can regulate humidity levels, mitigate the potential for mold, and facilitate a more comfortable interior while maintaining high thermal performance.

5. Environmental Sensitivity

ICF walls can be made with a variety of recycled materials that can minimize the environmental impact of the building. They use fewer natural resources, such as gas, electricity, and wood. ICFs can generate as little as 1% construction waste. They are also manufactured without the use of any CFCs or chemicals.

ICF Building Process

ICF construction is often considered less demanding than typical construction. Less-skilled labor can be employed to lay the ICF forms (although careful consideration must be made when pouring concrete to make sure it joins fully and cures evenly without cracking). Unlike traditional wood beam construction, no additional structural support is required for openings, doors, windows, or utilities.

ICF Cost

In most cases, ICF construciton will cost about 40% less than conventional construction, primarily because of the labor savings from combining multiple steps into one step. Above-grade ICF construction is typically more expensive, but when adding large openings, ICF construction becomes very cost effective. (Large openings in conventional construction require large headers and supporting posts, whereas ICF construction reduces the cost, as only reinforcing steel is needed directly around the opening.)

ICF buildings are generally less expensive over time, as they require less energy to heat and cool. Additionally, insurance costs can even be much lower, as insurance companies recognize that ICF homes and buildings are less susceptible to damange from earthquakes, floods, hurricanes, fires, and other natural disasters.

Effective in Construction

ICFs have been proven as an effective medium in construction. Over the last 10 to 15 years, close to 300 schools have been built with ICFs, frequently reducing their heating and cooling loads by 30% to 50%. School districts have also reported they're saving hundreds of thousands of dollars annually in operating costs. ICFs have also been effective with different varieties of tall wall buildings, such as churches, theatres, and resident buildings.

ICF systems are easy and quick to build, including a core process that can be completed in just a few steps. Using ICFs, many builders have shaved weeks off their build time, which means lower labor costs as well.

Interested in designing in Revit with ICF? View the library of ICF BIM resources on BIMsmith.

--

BIMsmith is a free cloud platform for architects, designers, and building professionals to research, select, and download building product data. Search, discover, compare, and download free Revit families on BIMsmith Market, or build complete, data-rich Revit wall, floor, ceiling, and roof systems faster with BIMsmith Forge.

BIMsmith is a free cloud platform for architects, designers, and building professionals to research, select, and download building product data. Search, discover, compare, and download free Revit families on BIMsmith Market, or build complete, data-rich Revit wall, floor, ceiling, and roof systems faster with BIMsmith Forge.

Comments