The following is a guest article from Rose Morrison of Renovated. Submit your own article or building project to be featured on the BIMsmith Blog.

The world will always need the building and construction industry. Still, despite how crucial it is to society, the sector has faced a labor shortage for years. According to the Associated General Contractors of America, 81% of construction companies have trouble filling open positions.

This labor shortage isn’t a new dilemma, but it’s getting worse. Fewer people are entering the industry while demand for new buildings continues to climb. The U.S. construction sector employs 11.2 million people, and that still isn’t enough.

Thankfully, construction companies can mitigate the effects of this shortage. Here’s how technology can help firms stay productive despite a diminished workforce.

Speeding Pre-Construction Phases

The labor shortage may affect the construction phase most significantly, but optimizing other stages can help mitigate it. By saving time in planning and pre-construction, you can start building sooner. This earlier start will help you stay on schedule despite having fewer workers.

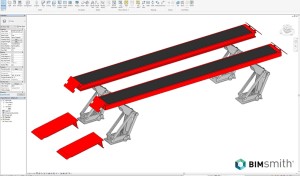

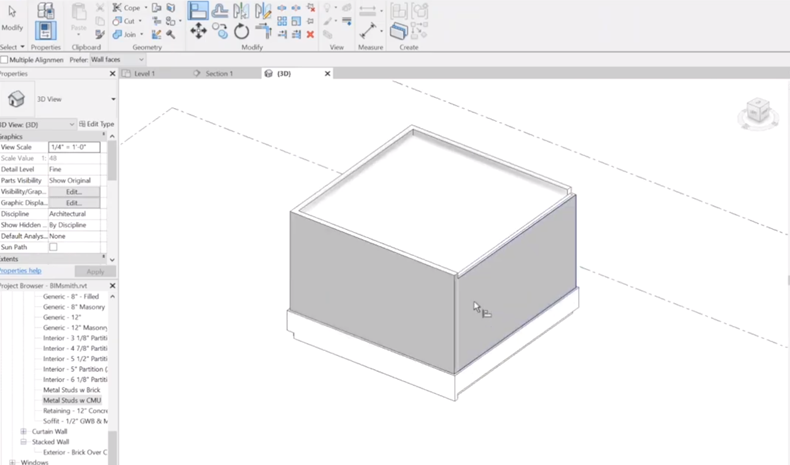

Perhaps the most crucial technology for pre-construction is building information modeling (BIM). With BIM software, you can create, edit, and share digital models far faster than any physical alternatives. These tools also provide a consolidated place to generate and send crucial reports.

One study found that BIM can lead to an 80% reduction in the time it takes to generate an expenditure report. Since clash detection features automatically highlight errors, it also prevents time lost to finding and fixing mistakes. Embracing these tools before construction begins can get a project started on the right foot, saving time from the beginning.

Preventing Rework

There are many factors behind projects’ tendency to run behind schedule, but rework is one of the most significant. Rework regularly costs construction teams four hours a week or more. That means that in a six-month project, rework can take up 12 or more work days’ worth of time.

Once again, BIM is the ideal technological solution here. Clash detection can reveal potential issues in the design phase, so you can correct them before they become more serious problems. It doesn’t take nearly as much time to fix a digital model as it does to rebuild a physical structure.

With a diminished workforce, rework has a compounding effect, as a larger portion of the team has to address the issue. If you reduce these time-consuming errors, construction teams will have an easier time staying on schedule.

Streamlining Training

While fewer people are entering the industry, that doesn’t mean construction teams can’t find any recruits. New hires are coming in, but training them takes time, further slowing project completion. Technology can help streamline the training process, letting teams reach their full productivity in less time.

Image Source: Pepper Construction

Augmented reality (AR) glasses project digital images or text in a worker’s field of vision. With these gadgets, new hires can see instructions or safety guidelines as they work. Since they have these constantly accessible reminders, they won’t need another employee to oversee them for as long.

AR can also provide accurate hands-free measurements of any structures or materials look at. This information will help recruits get a better understanding of their work without having to acquire years of hands-on experience.

Improving Safety

Injuries are some of the most common sources of construction delays. In 2018 alone, the industry saw 77,500 nonfatal injuries that resulted in at least one day away from work. Technology can make work sites safer, preventing these lost time incidents and helping a diminished workforce stay on schedule.

Internet of Things (IoT) sensors are some of the most helpful technologies in this area. These wireless devices can alert workers to safety hazards they may otherwise miss. For example, IoT-connected helmets or vests can measure body temperature, heart rate, and perspiration to warn workers to break before becoming exhausted.

Similarly, location sensors can warn workers when they get close to a hazard, like a moving vehicle. Since there were 9,050 forklift-related nonfatal injuries in 2017 alone, these warnings can prevent many accidents, saving workers and time. An injury-free worksite will be far more productive, countering the effects of the labor shortage.

Enabling Fast, Clear Communication

Communication has always been a weak point for construction, and one that exacerbates the effects of the labor shortage. Since construction involves various stakeholders, workers often need approval or insight from multiple parties before moving forward. Any delays in this communication can delay the project, and a diminished workforce needs all the time they can get.

Image Source: Techno FAQ

Thankfully, modern technology enables real-time, clear communication. With BIM software, you can send up-to-date digital models of a project to any collaborators instantly. Similarly, drones and IoT sensors can send pictures and other data to the cloud in real-time for someone far away to access it.

Digital twins of a project can show progress to stakeholders in real-time without them visiting the site in-person. All of these technologies provide more information than traditional systems and offer it faster. As a result, even the smallest of teams can stay ahead of schedule.

Finding Potential Workers

Finally, technology can help construction firms extend their reach in the hiring process. Job board websites like Indeed or Glassdoor can help companies find potential candidates faster than ever. Taking advantage of digital marketing can also help you appeal to a younger, tech-native audience.

Becoming a more tech-centric company is crucial in attracting the next generation of workers. A 2019 study found that 54% of Gen Z applicants won’t complete an application if they feel the recruiting methods are outdated. All-digital, mobile-friendly, and fast communication in the hiring process will help appeal to these potential workers.

The construction industry has a reputation for being “old-fashioned” and tech-avoidant. Embracing a broad range of new technologies will help fight this notion, helping younger applicants see its value. As more companies do this, the labor shortage could start to fade.

It’s Time for Construction to Embrace New Tech

For much of its history, the construction industry has been slow to adopt new technologies. Given the current labor shortage and how tech can help mitigate it, it’s time for that trend to end. If you can embrace the right tech, you can work around and even combat the construction labor shortage.

--

Rose Morrison

Rose Morrison is a construction and design blogger and the managing editor for Renovated. To read more posts by Rose, check out her blog.